Business Introduction

DESIGN SERVICES

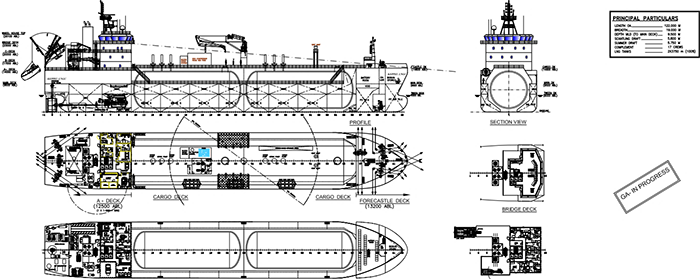

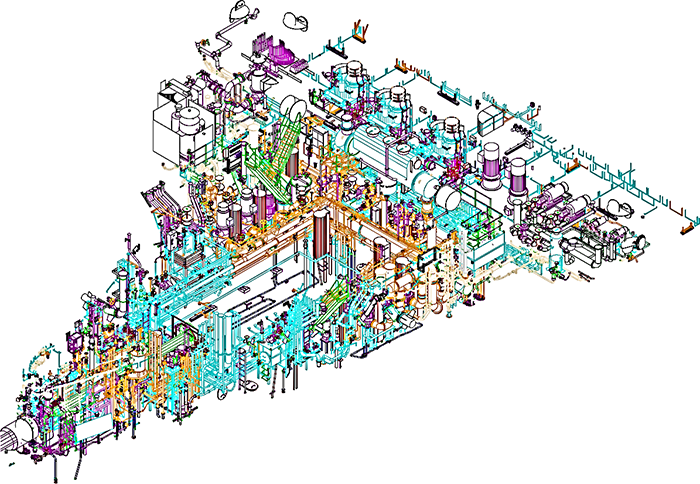

New Shipbuilding Design

-

1New Shipbuilding Design : Initial & Basic, Lines ,Structural Details, System Details, Production Engineering design

-

2Ship Type : Container Carrier, Oil tanker, Bulk Carrier, GasCarrier, Offshore Supply Vessels, LNG Fueled Ship, Electric Propulsion Ship

-

3Designsoftware : Napa, AutoCAD, Tribon & AM

-

4Engineering design : BLOCK DIVISION, Shipbuilding Detail Process, Crane lifting and transporter Movement of Heavy Block & Structure & Modules Quality accuracy drawing, Scaffolding drawing

Marine Water Structure and System Design

-

1Floating Dock, Dock Gate, Basic/Detailed/Production/Art Design of Water Pants

-

2Floating Dock Construction technology services” On-sea floating dock construction Method.

Engineering Detail

-

1Basic Engineering :

-

AOutline & Full Specification with Technical Support, Building Cost Breakdown

-

BP.O.S & P.O.R

-

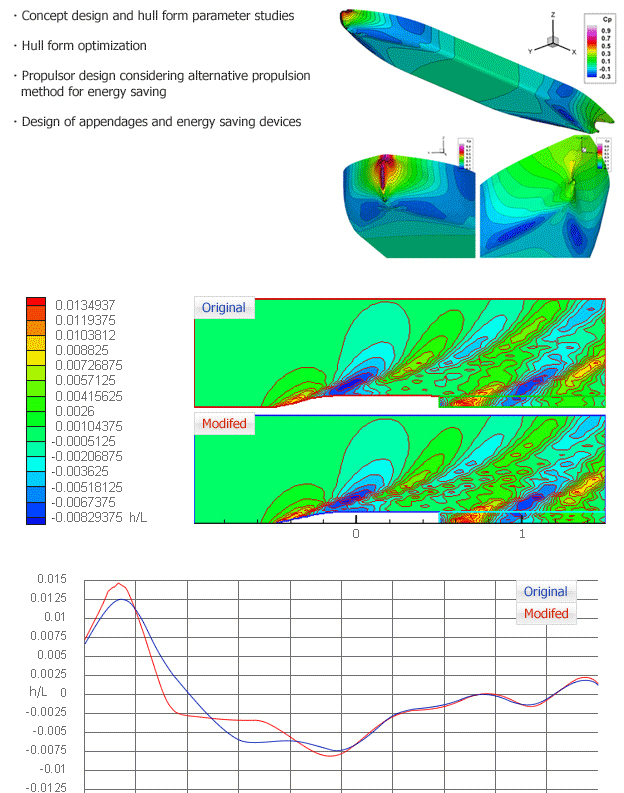

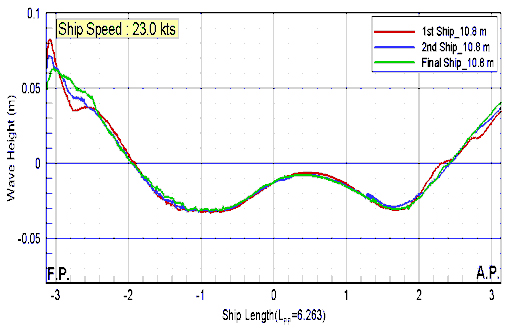

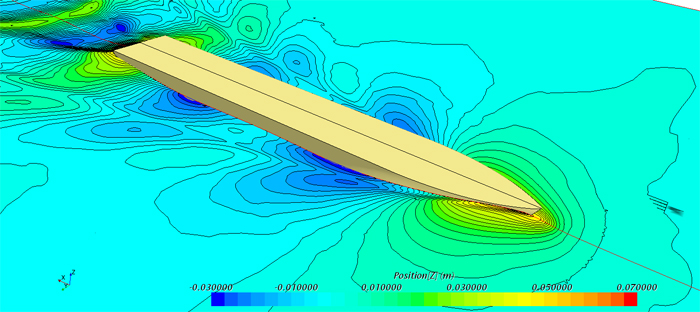

CHull form Development, Hydro Dynamic Analysis, Model Test

-

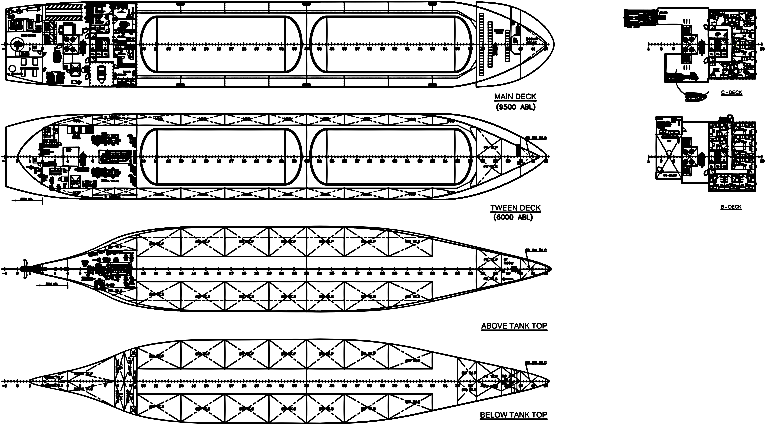

DGeneral Arrangement DWG, Lines Plan, Capacity Plan & etc.

-

ELoading, Damage & Stability Calculation with Longitudinal Strength Calculation

-

FLaunching/ Load out/ Re-docking Calculation (Dry Dock, Floating Dock, Skid Barge)

-

GLight Weight Control

-

HInclining Test, Ship Speed & Maneuvering Test in Sea Trial

-

-

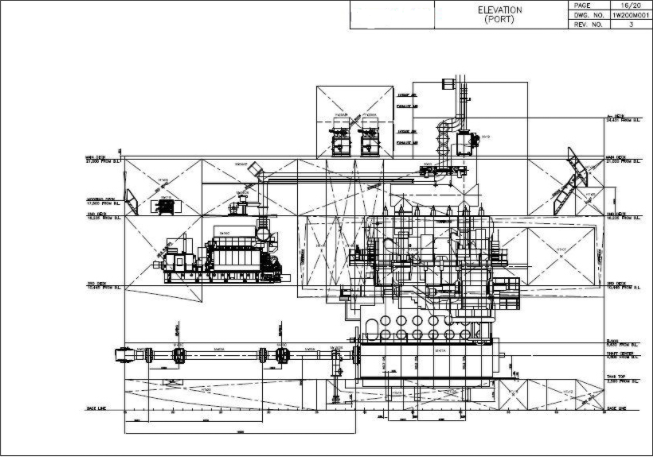

2Structural Engineering :

-

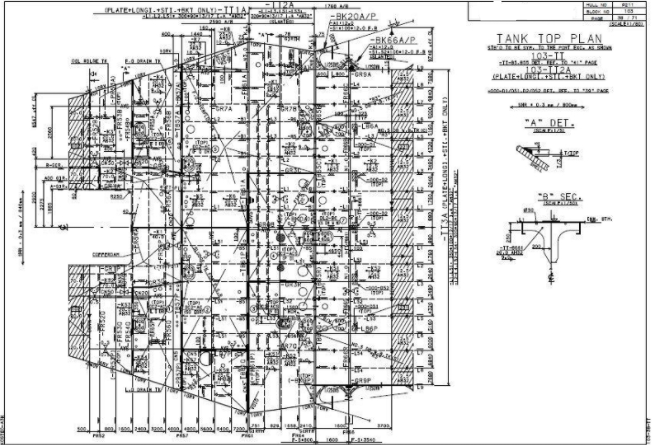

AKey Plan DWG (Midship Section, Construction Profile & Deck Plans, Shell Expansion)

-

BLongitudinal & Transverse Strength Calculation

-

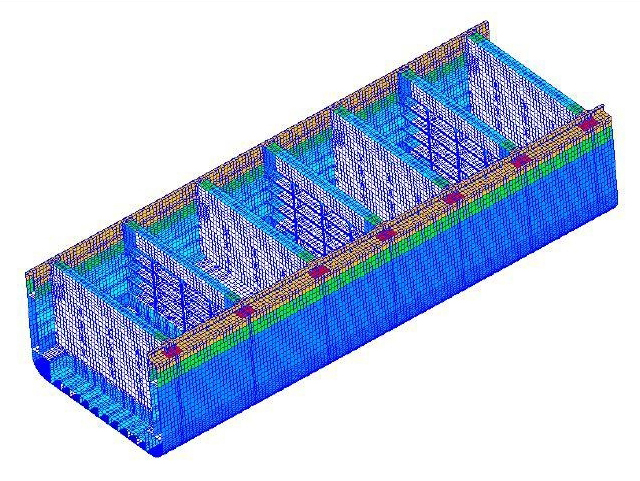

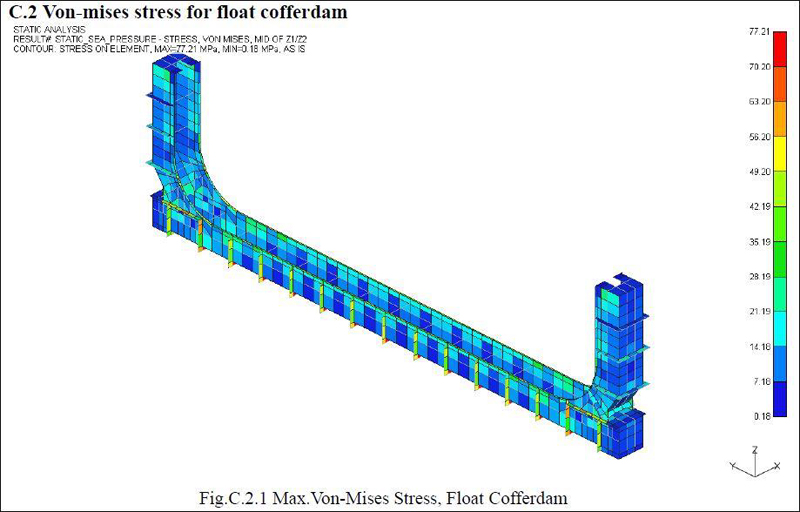

CWhole Ship F.E. Analysis

-

DCargo Hold F.E. Analysis

-

ESloshing F.E. Analysis

-

FFatigue Analysis

-

GStructural Detail Drawings

-

HLocal Strength Calculation

Figure 3.1 3-Hold Length F.E. Model

-

-

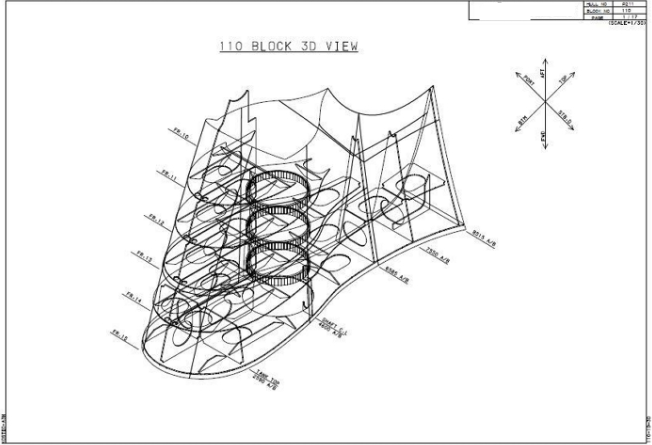

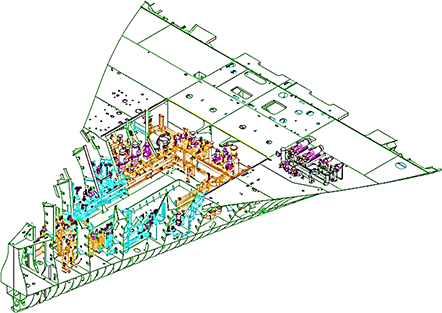

3Structural Production Engineering :

-

ATribon Modeling

-

BSteel & Material Control

-

CHull Production Assembly Drawing

-

DHull Production Nesting Drawing

-

EHull Production Standard Drawing

-

FHull Lines Landing & Fairing

-

GHull Light Weight Control

-

HPre-Outfitting Material Control(Manhole, Vertical Ladder, Step, Hand Grip, Hand Rail, etc.)

-

-

4Hull Outfitting Engineering & Hull Outfitting Production Engineering :

-

AAnchoring System Drawing

-

BMooring System Drawing

-

CCargo Hold Ventilation & Traffic System Drawing

-

DDeck Crane Drawing

-

EHatch Cover Drawing

-

FContainer Securing Drawing

-

GRoll On/ Roll Off Equipment Drawing

-

HSafety Equipment Drawing

-

IVentilation Drawing, Hull Outfitting Standard

-

-

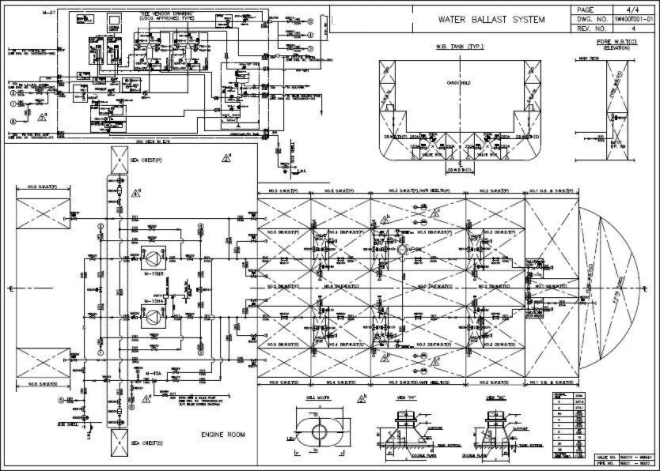

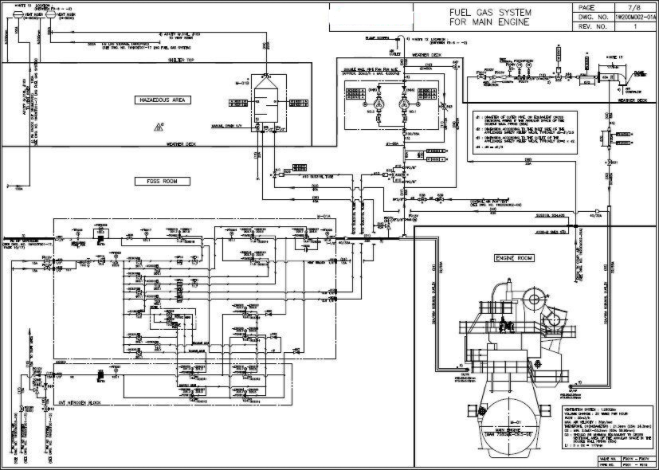

5Piping Engineering & Piping Production Engineering :

-

ACargo & Ballast System, Fire & Wash Deck System, Bilge & Scupper System

-

BDeck Service Air System, Air & Sounding System, Valve Remote Control System

-

CDeck Machinery Hydro System, Fresh Water System, Bow Thruster System

-

DGas Detection System, Steam Service & Condensate System, Tank Cleaning & Venting System

-

ECargo Monitoring System, Remote Sounding & Draft Gauging System, Inert Gas & Dry Air System

-

FWater Spray System, Dry Powder System, CO2 System, O.D.M.E System

-

GSystem Diagram in Engine Room

-

HValve List, Instrument List, Pipe Line List

-

IComposite Arrangement, Hole Plan, Package Unit, Ship Side Connection

-

JPipe Support, Steam Tracing, Piping Standard

-

-

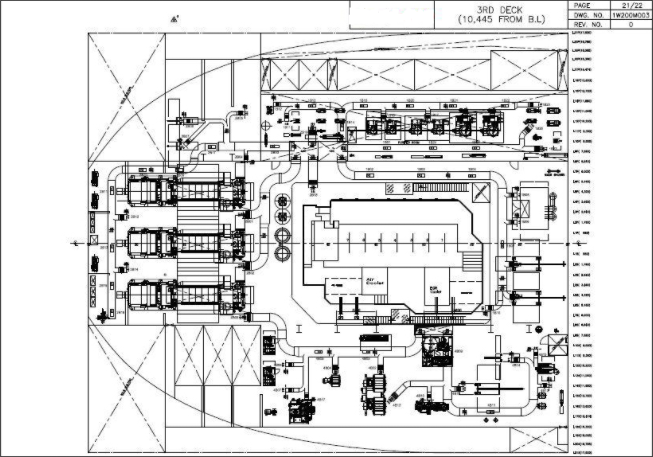

6Machinery Engineering & Machinery Production Engineering :

-

AMachinery Arrangement

-

BVentilation Arrangement

-

CExhaust Gas Pipe Arrangement

-

DInsulation Plan

-

EStowage Plan, Workshop & Store Arrangement,Arrangement of Lifting Beam

-

FDoor Plan, Top Bracing, Arrangement of Engine Casing, Arrangement of Steering Gear Room

-

GMooring Trial Procedure, Sea Trial Procedure

-

HMachinery Foundation, Traffic, Independent Tank, Room Equipment, Carling Plan

-

IMachinery Standard

-

-

7Electric Engineering & Electric Production Engineering :

-

AWiring Diagram (Power, Lighting, Control, Navigation & Communication, Fire & Alarm)

-

BConnection Diagram

-

CArrangement (Wheel House, Radio Room, Antenna, E/Sound & S/Log, Engine Control Room)

-

DInstallation Diagram, Cable Seat, Cable Way, Cable Plan,Cable & Material Control

-

EElectric Equipment Arrangement (E/R, S/G Room, Accommodation, Upper DK, Pump Room)

-

FCoaming Arrangement

-

GElectric Standard

-

-

8Accommodation Engineering & Accommodation Production Engineering :

-

AAccommodation & Engine Casing Arrangement

-

BColor Scheme

-

CFire/ Heat/ Sound Control

-

DSteel Outfitting Design

-

EFurniture Arrangement

-

FGalley Arrangement

-

GHVAC Arrangement

-

HAccommodation Standard

-

-

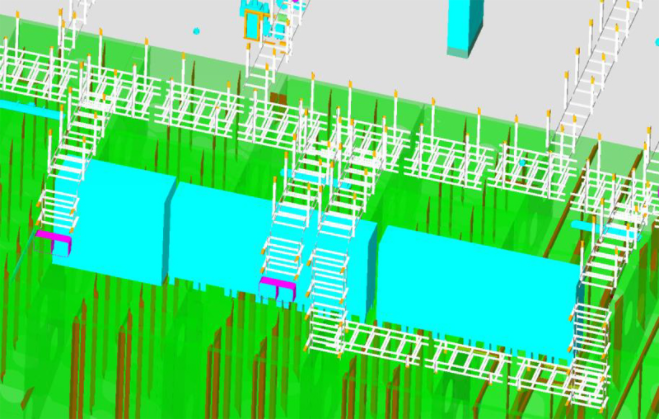

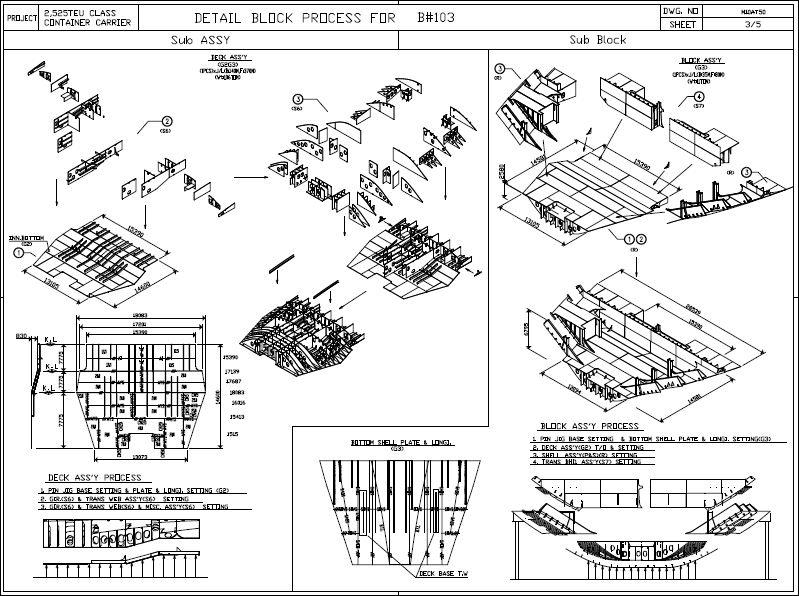

9Production Methodology Engineering :

-

ALifting & Support

-

BScaffolding

-

CAccuracy

-

DAir Leak Test

-

EArrangement of Temporary Hole

-

FBlock Division & List

-

GDBP (Detail Block Process)

-

HErection Support

-

IService Tower

-

JCofferdam for Half Ship Joint, Production Methodology Standard

-